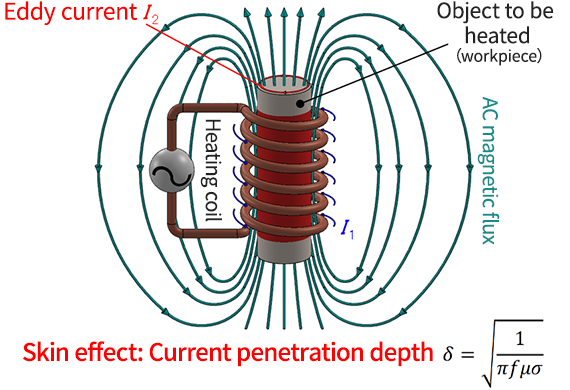

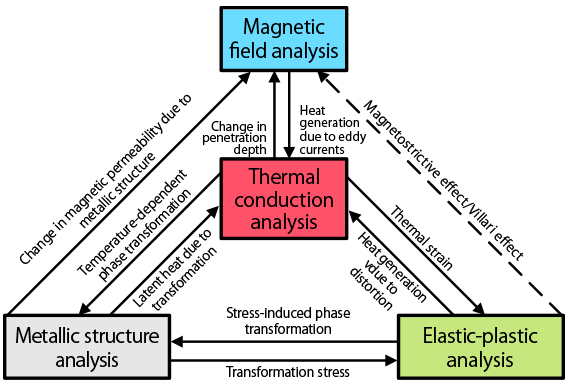

Neturen has developed and is using a highly accurate simulation system with the coupled analysis method of “Magnetic field” and “Temperature - metallic composition - stress/strain,” based on the Finite Element Method (FEM).

Based on commercial FEM software, the heat treatment analysis program is Neturen's proprietary technology. It incorporates the necessary functions for induction heat treatment analysis.

As a prediction tool for the complicated phenomena that occur in heat-treatment processes, induction heat treatment simulation is used to enhance the design of heat-treatment equipment such as heating coils and injection cooling jackets, and to improve the heat treatment quality, thereby reducing the number of prototypes required and cutting down on design and development time.

Analysis conditions such as workpiece rotation and heating coil movement are applied to a three-dimensional FEM model, and we can perform simulations under various heat treatment conditions.

- 拡大

- Principle of induction heating

- 拡大

- Coupled analysis system for simulating induction heat treatment

It possible to obtain a variety of information about the interior of the workpiece that is difficult to ascertain visually or by measurements. Analyzing these information changes in chronological order makes it possible to achieve even lower levels of heat-treatment distortion.

|

(1) Temperature distribution |

(2) Metallic composition and hardness distributions |

(3) Stress and strain distributions |

|

(4) Quenching distortion |

(5) Current and heat generation distributions |

(6) Magnetic flux density and magnetic field distributions |

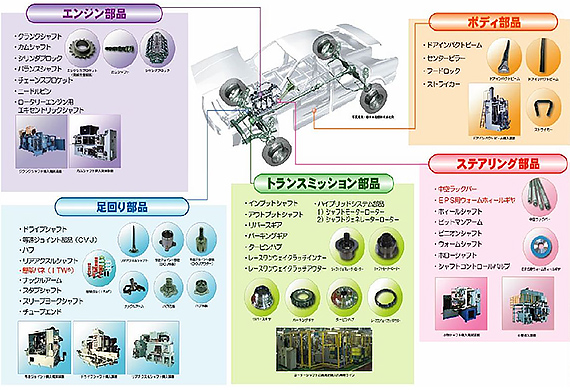

Three-dimensional simulation of induction heating in automotive/construction machinery parts