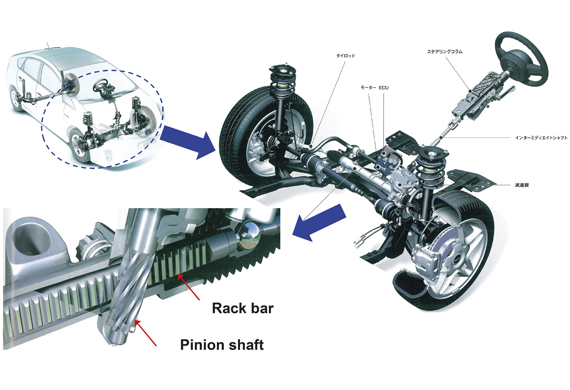

Induction heat treatment enables stable production control, while fine control of the material, shape, and pre-processing and pre-treatment (internal stress and pre-structure) of material allows less variation in heat treatment distortion, and "fixed" dimensional accuracy (stabilized distortion) is attainable. This is the “one-piece flow” process, in which one part is heated and cooled under controlled conditions.

Furthermore, "low (less)" distortion is also attainable by setting pre-processing dimensions and heating/cooling conditions that take into account the amount of distortion. Combining these achieves the "W-Tei® (stabilized and low) distortion" heat treatment feature.

Distortion that occurs during induction quenching significantly affects the final quality and performance of products, as well as the cost of high precision machining in post-processes.

Neturen has advanced heating and cooling control technologies and has abundant expertise in management of quenching distortion for a wide range of parts.