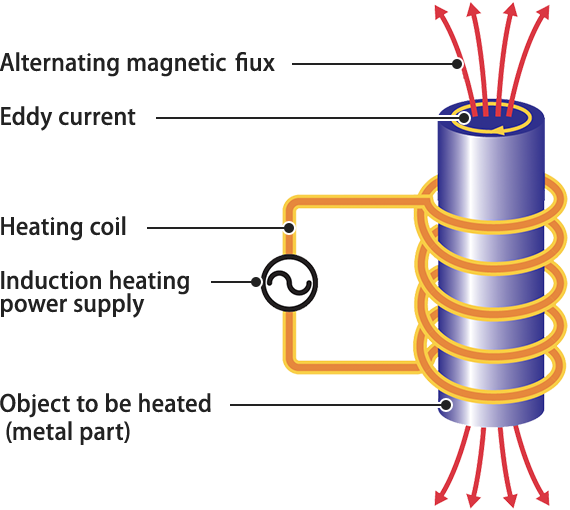

Using an induction-heating (IH) process that applies the phenomenon of electromagnetic induction, a steel part is rapidly heated to a high temperature in seconds and then rapidly cooled.

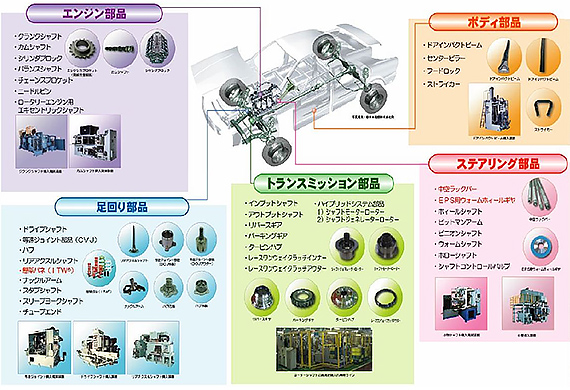

The surface of the steel parts can be hardened by this way. Induction hardening has been widely applied to improve the wear resistance and fatigue endurance of steel parts in such products as automobiles, construction equipment, machine tools, and so on.

In addition, it has attracted attention as W-Eco (Ecological and Economical) heat treatment method. This is because it features low CO2 emissions, a clean environment and environmentally-friendly technology, and it offers the advantage of energy conservation through outstanding productivity by a rapid heating using IH technology.

Self-heating, rapid and surface heating up to 1,000°C in a few seconds

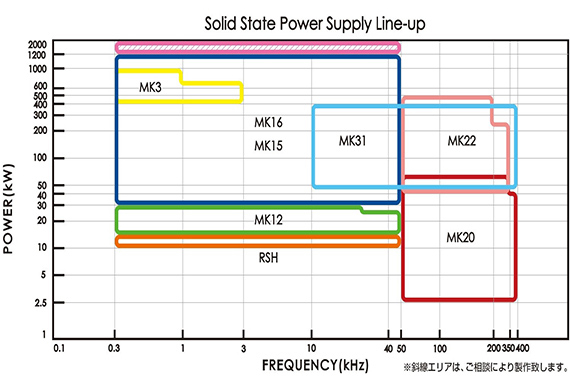

Combination of frequency, output power, heating coil and cooling system → Wide range of heating and cooling condition settings

Direct heating using electricity

Direct heating using electricity

Introduction of computerized control and in-line process

Development of the high-efficiency transistor oscillator

|

Advantage |

Main mechanical characteristics |

|||

|

Fatigue |

Friction |

Toughness |

Cost |

|

|

(1) High surface hardness |

◎ |

◎ |

✕ |

ー |

|

(2) Deep and adjustable hardened layer depth (Against carburizing and nitriding) |

Surface Fracture○ Internal Fracture◎ |

Rolling○ |

ー |

ー |

|

(3)High-level surface compressive residual stress |

◎ |

Rolling◎ Surface△ |

◯ |

ー |

|

(4) Microstructure (1) Grain size (2) Temper carbides |

◯ |

◯ |

◎ |

ー |

|

(5) Low decarburization |

◎ |

◯ |

ー |

◯ |

|

(6) Low deformation W (Double)-Tei (Stabilized and low) distortion |

ー |

ー |

ー |

◎ |

|

(7) Low material costs |

ー |

ー |

ー |

◯ |

◎ Highly effective ○ Effective △ Less effective/equivalent

× Adversely effective - Less related