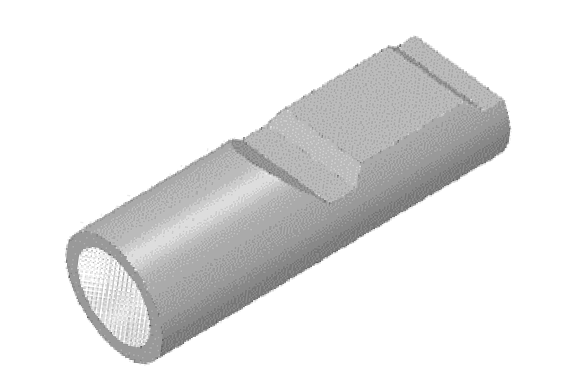

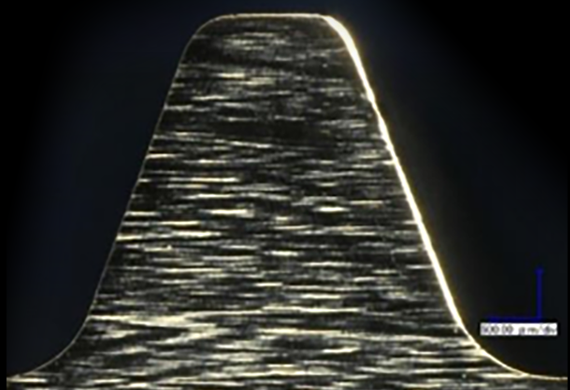

This is a cold plasticity forming technology where a die of an arbitrary shape is pressed against a pipe material and core dies of different height are inserted repeatedly into the inner-diameter side, so that the pipe wall is raised to the die and desired shape is achieved to a high level of precision.

Unlike hot forging, it does not require heating energy.

- High strength, high toughness, and high precision

- Saves processing time

- Thinner wall thickness, saves material

- Able to achieves shapes that are difficult for machining to produce

- Saves weight due to using pipes

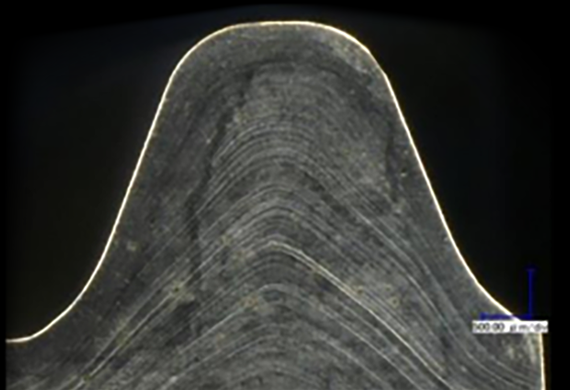

- Unlike machining, the cold incremental forming process forms continuous metal flow, which delivers high strength and high toughness.

- Further strengthening is possible when combined with induction heat treatment.

Since suitable dies are used, it is possible to manufacture not only tooth shapes but also various other shapes.

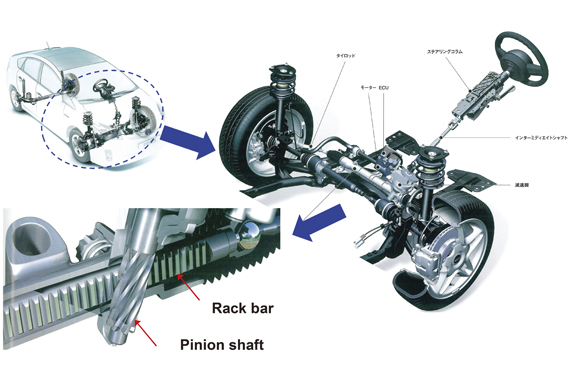

This process is used for forming the teeth of rack bars, which are the key part of steering systems, constituting an important safety component of automobiles.