Al dente shaped bar steel (Surface-layer softened steel) is heat treated bar steel with arbitrarily adjusted hardness along the cross sectional direction of the bar steel. (Patented)

- Thanks to significant improvement in the HE characteristics (hydrogen embrittlement), delayed fracture resistance is enhanced while maintaining high strength.

- Softened outer surface provides outstanding surface machining properties

(1) The softened layer has fewer hydrogen trapping sites and is less prone to crack initiation.

(2) No transgranular film-like carbides provides no transgranular delamination.

References:Y.Matsumoto,K.Takai,M,Ichiba,T.Suzuki,T.Okamura and S.Mizoguchi:Tetsu-to-Hagane,99(2013),236

Wire diameter: 7.0 to 40.0 mm

Product form: bar shape (max. 12 m) or coil shape (max. 2 tons)

Tensile strength: 1,230 to 1,420 N/mm2 or higher (standard value)

★ Excellent delayed fracture resistance

★Improves rolling tool life by 1.5 times (superior machining property)

Compared to our products

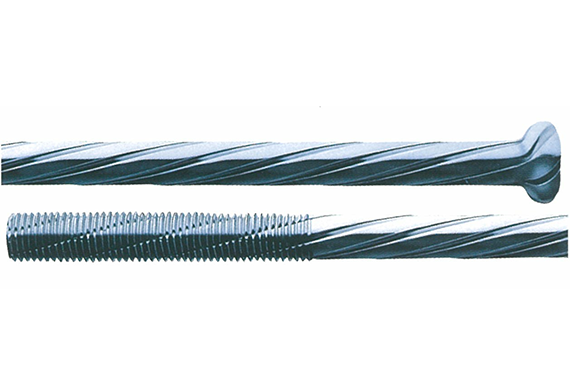

Size : φ5 to φ40 mm

Steel types: S35C and other structural steels, spring steels, stainless steels (hardenable bars)

Approximate strength (tensile strength): 1,200 to 2,200 N/mm².

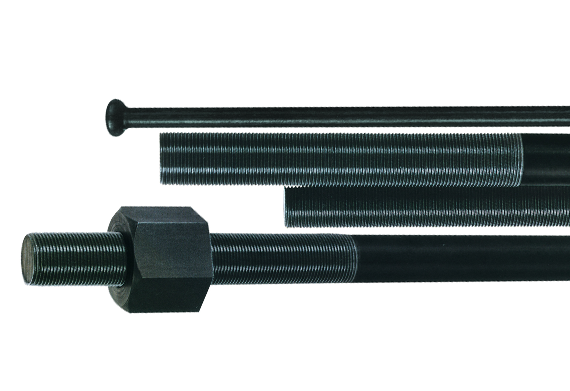

High-strength bolt (prototype)

Size: M12

Strength class: 14.9 equivalent

Tensile strength: 1,500 N/mm² (base material)

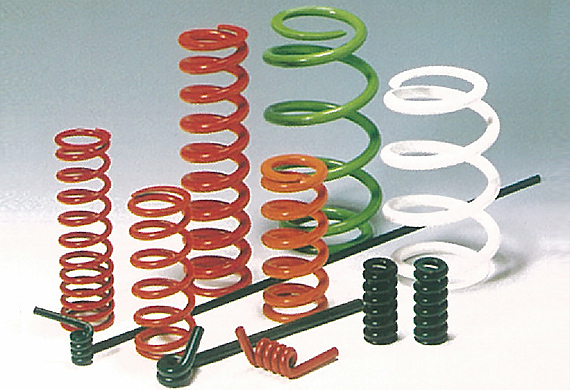

High stress spring (prototype)

Size: Height 300, inner diameter φ75, total number of coil turns 8, wire diameter φ12

Tensile strength: 2,150 N/mm² (wire)