As a pioneer of high-strength shear reinforcement, we have contributed to the development of high-rise RC buildings.

The highest grade of steel bars in Japan, "1275 N/mm2," reduces the weight of members and enables streamlining of design and construction.

The only shear reinforcement in Japan with the highest strength (yield point or 0.2% proof stress: 1,275 N/mm2 or higher).

Manufactured under one of the most advanced quality control systems in Japan to ensure stable and high strength.

We have established a damage-control design method (experimental formula) to evaluate "residual shear crack width.

Material strength in the 1,275-N/mm2 class (sufficient elastic range) is effective in controlling residual cracking.

When compared to 785 (685) class high-strength shear reinforcement bars, the ultimate shear strength can be increased.

The amount of reinforcement required can be reduced, which leads to improved economic design and workability.

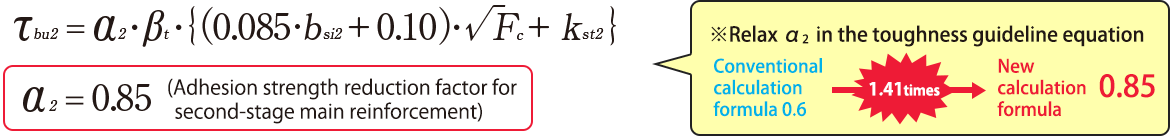

In beam members that use ULBON 1275, the required bonding length of the cutoff length of the second-stage main reinforcement can be determined using a unique calculation formula (experimental formula), enabling rationalization of design and construction.

Saves on joint costs (material and construction costs), as well as labor-hours to install!

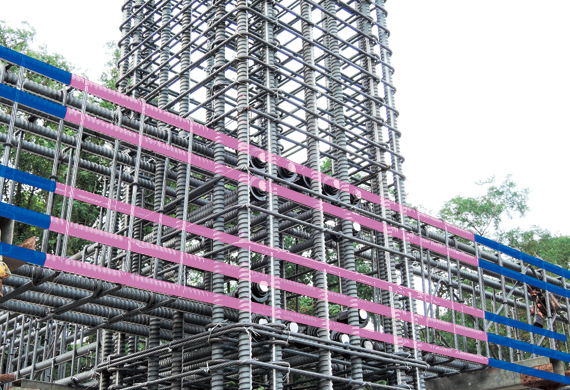

The optimal wire diameter can be selected according to the cross-section of the part, etc

Six spiral groove shapes unique to ULBON.

Can be distinguished from other reinforcing bars in appearance.

We have established a stable supply system throughout Japan from the Iwaki Plant in eastern Japan and the Ako Plant in western Japan.

We are working to further improve the quality and supply capacity by automating manufacturing facilities and introducing other productivity enhancements.