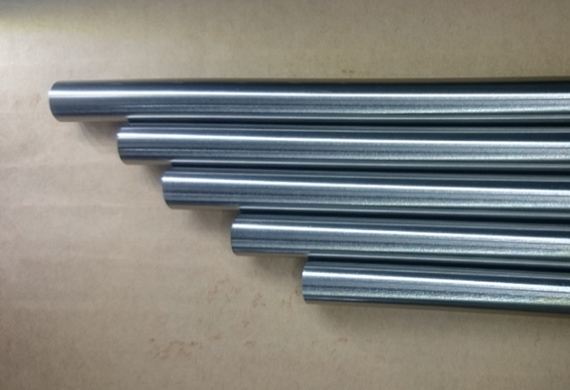

Neturen manufactures and sells products that are heat-treated by high-frequency induction heating of special steel and other steel materials to achieve outstanding straightness and high roundness accuracy through centerless grinding.

Customers have applied various types of processing, and the products are widely used for small motor shafts, plastic mold ejector pins, and other applications.

Even heat-treated and fine-diameter materials are provided straight.

We perform centerless grinding to provide materials with excellent roundness.

In order to provide materials close to finished products, we have established an integrated manufacturing system that includes material procurement, pultrusion processing, heat treatment, bend correction, centerless grinding, and fixed-length cutting.

- Reduces administrative work, such as outsourcing processing instructions

- Reduces haulage costs

- Improves yield by reducing scrap caused by bending

- Helps to reduce lead times and the like.

Quenched steel pipes with outstanding straightness are available.

Centerless grinding is also available.

The combination of Neturen's high-frequency induction heating technology + centerless grinding technology results in materials with excellent straightness and roundness.

![Black leather products [products left after heat treatment]](/en/products/steel/pre-hardened/main/0/teaserItems1/0/binaryNodeName/products_steel_pre-hardened_img_01.jpg)